When choosing glazing for fire rated areas, stairwells, or industrial spaces, wired safety glass remains a practical and cost effective solution. I have seen clear wired glass used successfully in factory partitions, school corridors, and fire exit doors where containment and visibility are both required.

This guide explains how wired safety glass works, where it performs best, and how to select the right specification for your project, using real world installation and maintenance considerations.

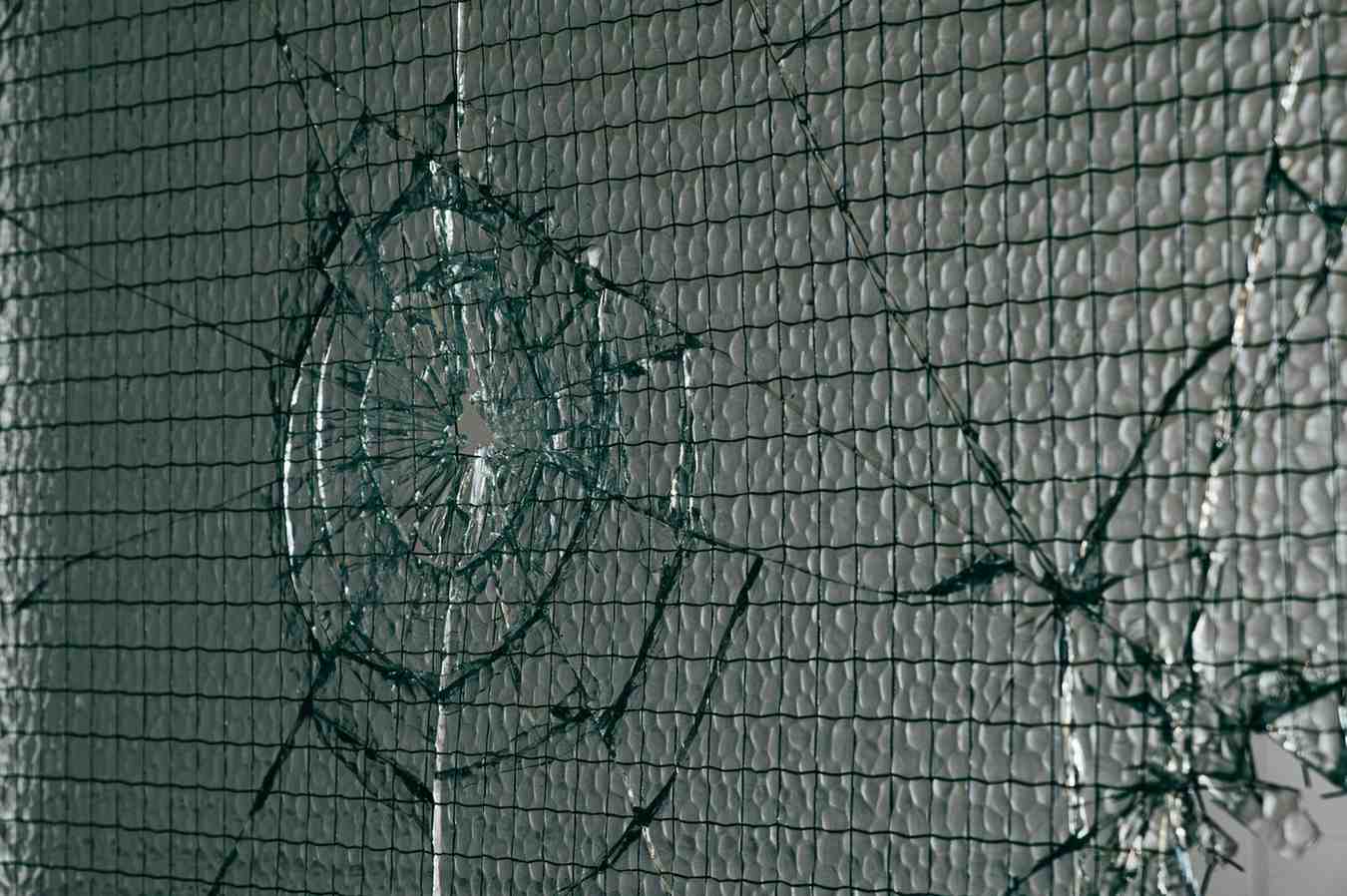

Wired safety glass can come as patterned glass or clear wired glass, where a steel wire mesh is embedded inside during manufacturing to maintain structural integrity under fire or impact. The wire is rolled into the molten glass so it becomes part of the pane, not an added layer.

This internal mesh helps the glass stay in place when cracked, which is why fire rated glass applications often specify wired variants for containment and integrity.

The production process involves feeding metal mesh into molten glass as it passes through forming rollers. This creates uniform wire spacing and consistent panel thickness across the sheet.

This method supports heat resistant glass performance by improving stability when exposed to sudden temperature changes in industrial environments.

One of the biggest advantages of wired safety glass is its ability to remain intact during fire exposure for a limited time. The wire holds cracked sections together, slowing flame spread.

For regulated zones, this containment supports fire rated glass assemblies when combined with certified frames and door systems.

When broken, the fragments remain attached to the wire mesh, reducing the risk of falling shards. This is different from float glass that collapses immediately when cracked.

However, it is important to note that impact resistant glass performance is lower than tempered or laminated alternatives, so correct placement is essential.

The embedded mesh helps the glass resist thermal shock better than ordinary glazing, which is why thermal shock resistance in wired glass is valued near heat generating equipment or sun exposed industrial facades.

For warehouses and workshops, this property helps maintain panel integrity during sudden temperature changes.

Wired safety glass offers several practical benefits when installed in the right environment and with proper framing systems.

In older commercial buildings, it is still widely used because replacement panels are affordable and easy to source.

While useful, wired safety glass is not suitable for every application and modern codes often limit where it can be installed.

The wire can create stress points that actually reduce impact strength, meaning it can break more easily under direct force. In high traffic areas, safer alternatives are usually recommended.

In some cases, exposed wire edges after breakage can cause injury, which is why newer laminated safety glass products are preferred for schools and hospitals.

One of the most common uses of wired safety glass is in fire exit doors and stairwell windows, where fire door glazing must provide both fire containment and clear visibility for safe evacuation.

I have personally specified wired panels in metal fire doors where budget constraints did not allow for ceramic fire glass systems.

Factories often use clear wired glass in internal walls to separate machinery zones while maintaining supervision and natural light, making it ideal for spaces where fire safety and visibility are both priorities.

For large facilities, it integrates easily into warehouse glazing systems with metal framing and safety barriers.

In certain industrial buildings, wired glass is installed in overhead panels where containment of broken glass is important if cracking occurs.

However, modern safety codes may require laminated roof glazing instead, so always verify local regulations.

Tempered glass is heat treated to increase impact strength and breaks into small blunt pieces. It is safer for human contact but does not provide fire containment.

Wired safety glass offers better integrity during fire but lower impact resistance, making location selection critical.

Laminated safety glass uses an interlayer to hold fragments together and provides better security and acoustic control. It is safer in occupied spaces, while wired glass is more suitable for containment focused applications.

Selecting the correct product depends on building codes, risk exposure, and functional requirements.

Not all wired glass carries certified fire ratings. Always confirm test standards such as BS or EN classifications before specifying panels.

For assured compliance, source from trusted glass suppliers in UAE who provide certified wired safety glass tested for fire-rated assemblies. Fire doors usually require tested glazing assemblies, not just glass alone.

Avoid installing wired safety glass in areas where people can fall into it, such as gymnasiums or children’s facilities. For offices and retail, laminated options usually provide safer compliance.

Proper metal framing and glazing beads are essential to maintain fire performance and fragment retention. Even the best glass fails if installed in non compliant systems.

With correct installation, wired safety glass can last decades with minimal maintenance. Regular cleaning prevents dirt buildup along the wire mesh lines.

Avoid harsh chemicals that may accelerate corrosion if moisture reaches the wire. In coastal or humid environments, protective coatings or sealed framing help extend service life.

Despite newer technologies, wired safety glass remains relevant in specific controlled environments where cost efficiency and basic fire containment are priorities.

Modern projects often combine it with advanced systems, using wired panels in secondary partitions and premium fire glass in critical exit routes. The key is correct specification, not blanket use across all glazing areas.

Wired safety glass is fire resistant glazing with embedded wire mesh that holds cracked panels together, making it suitable for fire doors, stairwells, and industrial partitions where visibility and containment are both required.

Wired safety glass is glass with a metal mesh embedded inside, designed to hold the glass together if it cracks. It is commonly used in fire doors, stairwells, and partitions for containment and visibility.

It has lower impact resistance compared to tempered or laminated glass and can cause injury from exposed wires if broken. Some designs may also distort visibility slightly.

Wired glass is fire resistant, retains fragments when broken, resists thermal shock better than ordinary glass, and often comes in clear wired or patterned styles for functional or decorative use.

Wired glass is not stronger in terms of impact; it mainly improves fire containment and maintains integrity during breakage. For high im,m,,,.pact areas, laminated or tempered glass is preferred.

Choosing the right glazing is essential for safety, compliance, and long-term durability. Wired safety glass remains a practical solution for fire doors, stairwells, and industrial partitions where containment, visibility, and budget considerations are important.

For professional guidance on selecting, installing, or maintaining wired glass, clear wired glass, or other fire-rated glazing solutions across the UAE, Murtaza Glass & Frames Trd. L.L.C offers expert advice, certified materials, and reliable installation services.

Contact our glass experts today to request a quote and ensure your project meets both safety and performance standards.

Discover professional guides on glass solutions, from doors and partitions to balustrades and windows, helping you choose the perfect style for your home or business.